For 100 years, Dairyman’s Supply Company has supplied industries, transitioning from dairy farmers to shed/portable building manufacturers.

It’s no secret that it’s not easy for businesses to last. The average staying power for companies in the United States has dropped to 12 to 15 years.

According to the U.S. Bureau of Labor Statistics, only 36 percent of businesses last 10 years. And it only gets worse from there.

Only around 21 percent make it to 20 years. The U.S. Census Bureau has found that maybe 12 percent of companies in the United States are 26 years old or older.

Care to guess how many companies last 100 years? It’s difficult to confirm, but most estimates are that only half of a percent (.5%) make it to the century mark.

Dairyman’s Supply Company Inc., a supplier of portable building components with main locations in Mayfield, Kentucky, and Gadsden, Alabama, plus several reload locations across the country is celebrating 100 years of business in 2025 with the fifth generation of the founding family being involved.

How has Dairyman’s survived over the past 100 years? According to President Greg Cook, the people in the company have made the difference.

“For many years, our sales and marketing materials have included the slogan, ‘Our people make the difference,’ and they truly do,” he says.

“We currently have 22 employees who have been with us for a minimum of 25 years. Thirteen of those have over 30 years of dedicated service to Dairyman’s Supply.

“Words cannot adequately express my sincere appreciation and gratitude for what these men and women have done for DSC.”

And by doing so, these folks have positively affected the shed/portable structure industry.

But like many industry-related businesses, the company’s offerings changed. Dairyman’s initial focus (as the name implies) was on the local dairy industry.

In fact, the shed-building industry didn’t really exist at the time, but the company’s progression to supplying materials for sheds was almost unavoidable.

EARLY YEARS

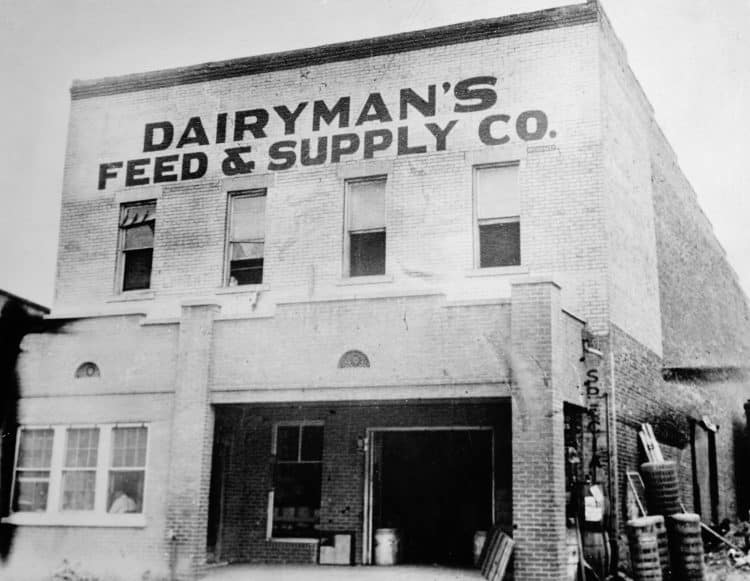

Two brothers-in-law founded Dairyman’s in 1925.

The dairy industry was growing in the Graves County area of Kentucky, so Coy Cook and Curtis Boyd launched a business in Mayfield to supply goods and services to that industry.

They called it Dairyman’s Feed & Supply.

“My great-grandfather started the company servicing dairy farmers,” shares Matt Cook, vice president-specialty sales for the company and Greg’s cousin. “He was selling them seed, fencing, stuff like that. There was some building material, but it was not a building material supply place.”

What the brothers-in-law couldn’t have predicted was that not long after opening their doors, the U.S. economy would be rocked by two major historical events: the Great Depression and World War II.

It was during these times that Dairyman’s would show a flexibility—and a determination—that would keep the business going.

“The Depression hit pretty soon after he started the business, and he was literally buying whatever was available,” shares Matt. “I think he bought railcars full of cans of beans. Whatever he could get.

“You know how there’s been allocation recently with COVID? Things were like that then, too. There was a limited amount of supply.”

After the Great Depression, the company added agricultural-related products and increased its sales volume and geographical footprint.

“Of course, then they went into World War II,” says Matt, “and it was the same thing there because a lot of steel and products were going to the war effort.

“It was some dicey times, but they survived. It kind of slowly morphed into what he was able to get, which was some building materials and that sort of thing. We barely survived.”

After World War II, the company would experience another shift that would continue to change the course of its business.

BUILDING MATERIALS SHIFT

As more homes and businesses arose from the post-war boom, the company became the “go-to” place for building materials.

These materials included residential roofing, nails, metal roofing, and siding. And the company’s service area expanded beyond Kentucky into Tennessee and Missouri.

So, in 1947, seeing tremendous growth in supplying materials, the second generation of family ownership shifted its focus and changed the name of the company to Dairyman’s Supply Company.

By 1959, Dairyman’s was established as a major building materials supplier. Added products that provided significant growth in the business were ceiling tile, flooring, and insulation.

From the 1960s through the 1990s, Dairyman’s continued growing at a solid pace. The company regularly had to add warehouse space and purchase property for growth. These included a 1978 purchase of 40 acres in Mayfield to increase its warehouse space. In 1983, the company opened a second location in Gadsden, Alabama.

“We didn’t sell lumber until probably the early ’80s, and that’s 90 percent of what we sell, now,” shares Matt. “It’s a commodity, a market-driven thing. You can win, or you could lose. But, it’s a good place to be.”

Greg says, “My father, his two brothers, and Curtis Boyd grew the company into a viable two-step distributor selling retail lumber to dealers in Kentucky, Tennessee, Illinois, and Missouri.”

In 1995, Dairyman’s Supply Company topped $100 million in annual sales for the first time.

But in the 2000s, something happened that would accelerate the company’s growth arc.

SHED BUILDING SUPPLIER

What happened? In 2007, Dairyman’s entered the shed/portable building market.

“It was just good fortune,” Matt admits, “because we’re right here in the cradle of it. You know, Derksen is right down the road, and a lot of the big, national shed builders are off of their tree. They taught them how to do it. They were salesmen for them, builders for them, and then broke off.

“Then you have Graceland, Premier, Old Hickory, Backyard Outfitters, so we were here from the beginning. And when they grew, like when they went to Texas, we followed them there and put a reload there.

“We were kind of able to organically grow with them. Really, it was Derksen’s and luck.”

The company bought a precision-cut saw, allowing it to provide cut-to-length framing components to shed builders. Flooring, siding, and sheathing were added to the inventory, making Dairyman’s a full-service distributor for the shed industry.

In just 10 years after entering the market, the company’s annual sales reached above $250 million.

“It’s an incredible industry,” Matt says. “It’s been life-changing for Dairyman’s. It’s doubled our business in a short period of time. We’ve been in business for a hundred years, and we’ve been doing this for almost 20 years. It’s given us a bigger area to service because we were just within 150 miles of Mayfield and Gadsden, and now we’re across the country.”

By 2022, Dairyman’s had a combined 500,000 square feet of warehouse space with additional inventory at its reload network sites in Shelby, Montana; Cresson, Texas; Minneapolis; Memphis; Glendale, Arizona; and Eugene, Oregon.

“Here and in Alabama, we service independent lumberyards within about a 150-mile radius,” Matt shares. “At the reloads around the country, that’s straight shed, and it’s all outsourced. We buy the material and ship it there, and truck it out.

“We have moved (reloads) a little bit, but when we find one that works, it tends to grow. Once you get a place there and get the product on the ground and customers are aware of you, you get more business. Every one of them has been in growth mode since we started.”

DAIRYMAN’S TODAY, TOMORROW

Today, Dairyman’s continues to focus on supplying the shed/portable building industry, continuing to grow its sales while maintaining outstanding customer service.

“We have an incredible business that was built by the forefathers,” Matt says. “A successful, conservative business, so we’ve always been able to have plenty of credit so when this business popped up, we were able to take it on.

“We’re very conservative, customer-driven, that’s the No. 1 priority. And our employees and our vendors. We put those as the top three priorities, and that strategy has worked.”

He also credits the company’s laid-back culture for some of its success.

“It’s a good culture. It’s a laid-back culture,” says Matt. “We don’t have a huge hierarchy, tons of bosses. Everybody has autonomy to do their job, which I think makes for a happier worker.”

That same style has also been key for the family to reach five generations of being involved.

“I think it’s because of the type of people we are,” shares Matt. “We’re just kind of laid back. We all like each other. It’s kind of weird. We get along, and we all work hand in hand.”

“We have eight family members active in the business now and almost all of them spent their summers in high school and college working here and learning the business,” says Greg.

“And, we’re good at what we do,” adds Matt. “It’s not rocket science. There’s a lot of repetition, but we’re pretty good at it. We service the customer really well.

“I just feel a lot of pride to be able to keep it going, pass it on to the next generation.”

And in the next 100 years?

“I bet we’re still here,” Matt says. “I would put money on that.

“We want to continue to grow with our current customer base and service them. We’re looking for any new things down the pike. We’re looking to our customers. We’re looking to our vendors, if we feel like there’s a need. There’s always something in the pipeline.”

“Working for a successful family business generates a sense of great pride but it also brings significant responsibility,” Greg concludes.

“The generations have all unselfishly committed to growing the business while still incorporating the principles, beliefs, and vision of the founders. We want to continue to move the company forward as all previous generations have done for us.”