Lumbermen Associates is a wholesale distributor with locations in Bristol, Pennsylvania, and Crewe, Virginia. At its 21-acre location in Bristol, the company ships 35 truckloads of lumber and sheet goods each day to a variety of customers, including lumber retailers, box, pallet, crating manufacturers, and shed builders.

Lumbermen’s has remanning capabilities to serve the shed industry with cut-to-length and custom-sized lumber. The company has been serving the shed and portable building industry for over 25 years. Providing quality lumber at fair pricing has been its goal and its biggest challenge.

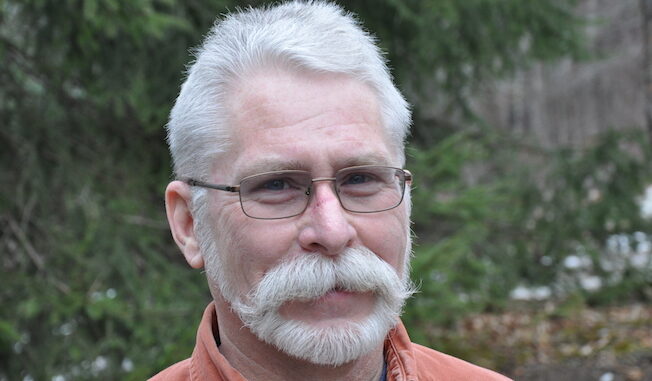

With experience like that, Shed Builder Magazine spoke with Lumbermen salesman, Dean Fry, about buying quality lumber for shed building.

Fry has an associate’s degree in forestry and has been working in the wholesale lumber and plywood industry for 44 years. For the last 28 years, Fry has worked exclusively in the shed and portable building industry, and his concentration has been with the shed industry in Pennsylvania for the past 22 years that he has been a salesman for Lumbermen Associates.

What types of lumber do you most often sell for sheds?

For framing the shed we rely on Euro Spruce and Domestic Premium SPF for most of our shed customers. This provides high-quality material at reasonable cost with little waste from excessive wane, planer chatter, or twisted material.

Treated lumber is available in Micro and CCA treating. Mostly in a #2 grade, 2 by 4 can be cut to length for floor joists to each customer’s specifications. The large majority of 4 by 4s sold is in the #2 grade. We are the largest stocking distributor of Louisiana Pacific products in the East.

For siding, we stock 7/16- and 3/8-inch LP Smart Panel products with raw OSB back, Silver Tech, with a foil back and Smart Finish, a brown MDO back. Stocking size panels range from 6 feet to 10 feet. From Roseburg Forest Products we also stock 5/8 and 15/32 Duratemp in 8-inch OC, in panel sizes from 7 feet, 8 feet and 10 feet.

LP Smart Floor in 19/32- and 23/32-inch in Square edge, and T&G and Georgia Pacific 5/8-inch V600 Yellow Pine Underlayment are stocked for floor applications.

Fiber trim in 5/4- and 19/32-inch and lap siding in 6- and 8-inch, both available in Smooth and Cedar textures, round out the LP product line.

Roof products include OSB and Yellow Pine rated sheathings and LP’s TechShield, a radiant barrier OSB sheathing. Shingles from GAF in both Architectural Timberline and three-tab Royal Sovereign are also stocked.

How can a builder be sure they are getting quality lumber? What should they look for?

Experience is a big factor. Buy from a supplier that specializes in serving the shed industry.

Unlike most construction, a shed has exposed framing lumber on the inside in most cases. This requires the best quality material because the shed buyer can see the quality of the materials.

We buy from only a few select lumber mills to insure we get consistent quality. The LP Smart products have industry-leading specifications that give their products resistance to fungal rot and decay with their SmartGuard system. A 50-year warranty on LP Smart Products guarantees consistent quality on all their products.

Lumbermen’s has promoted these products to give shed builders confidence that they are buying the best siding, flooring, and trim products in the market.

What are some common mistakes made when selecting lumber for sheds?

Stay away from buying material from an unknown mill, from an unknown supplier. This rarely pays off.

Keep records of the mills you like and the ones you do not. A reputable supplier knows what mill he is selling and what quality you expect.

Be specific in your requests. If you want plywood sheathing from a specific mill, tell them what mill. This saves the supplier time in sourcing, and you get the material you want. In Euro lumber, some mills mix Pine with Spruce, others separate them. Be clear as to what species you want.

Know your mills, know your supplier.

What recommendations do you have in terms of timing of purchase and amount of lumber?

The trends we had 25 years ago that we followed for purchasing large volumes at a certain time of the year has seemed to disappear. The world economy that we now have and the increased volume of import and export that we now experience have changed the rules.

The mills have been coming into the market differently. An optimizer at the saw mills can fine tune their output to better manage volume of specific sizes. There seems to be more communication between the mills and the wholesalers. They often come to us seeking information from us to plan their production.

There was a time when, if you wanted to buy a quantity of 4 by 4 treated, you bought in October or November. This was traditionally the best time to buy. This no longer applies.

The most important factor is to recognize a great deal when you see one. Keep records of your purchasing. Know what the “bottom” is for each item. For example, if your records show that the lowest price you paid for 4 by 4, 16-foot #2 treated is $550/m, in the last five years, and the highest is $755/m and you see a $560/m market, do not be afraid to buy quantity.

Buy as you need is a great way to control inventory value and storage space, along with managing cash flow, but being willing and able to “buy in” on specials helps keep your overall material costs down.

The timing of volume buying can bridge periods of market spikes. April and May for years had been a time of high plywood prices. If you could buy-in enough plywood at a good price in February or March to get you past the April-May spike, you could save hundreds or even thousands of dollars.

What recommendations do you have for storage and handling of the lumber to maintain quality for construction?

No one ever seems to have enough storage room. Store under roof whenever possible. Keeping moisture off the units will make it stay in good condition and keep molding at a minimum.

If you are stacking your lumber and sheet goods outside, keep them as far off the ground as possible. Using 6 by 6s as runners will help keep that bottom unit from getting or staying wet.

Rotate stock. Don’t let those last four units of 2 by 4, 8-footers stay in the back row. Pull them out before you put more in!

Any final thoughts when it comes to lumber for shed building?

Buy the highest quality you can get; it always pays off.

Know the market, your supplier, and the mills you like. Watch out for special deals from unknown sources.

Develop relationships with your suppliers. We can all learn from each other.

Consider volume buying on certain products to bridge high price market times.

The goal is to buy at the right price at the right time to make your company as competitive as possible and have some fun!