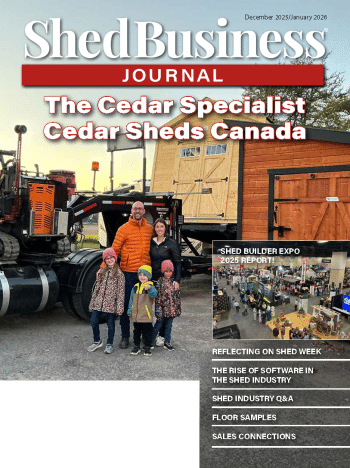

When Charles Meilleur shifted his family’s sawmill operation to building white cedar sheds, no one could have predicted the results.

In 1945, Charles Meilleur’s great-grandfather bought a steam-powered mill in Kiamika, Quebec, Canada.

As the years passed, his grandfather, and then his father took over the operation.

Meilleur joined the family business in 2009 with an idea in mind.

“I was looking for something to promote our white cedar,” he says. “My father sold cedar to contractors and customers and also produced docks. In 2010, I started building high-end hunting shelters.

“However, it was difficult to launch as a product, since I didn’t have any specialized equipment. One evening at a restaurant in 2012, a friend asked me, ‘Why not make high-end cedar sheds?’”

The Friday after that conversation, Meilleur built his first 8 by 12 shed—and sold it two days later.

“I delivered it with the sawmill boom truck,” he shares. “That day, I realized I was going to change the sawmill business to build sheds. Now, 70 percent of the cedar that comes out of the sawmill goes directly to the shed shop, and the remaining 30 percent is sold to customers for siding, patios, sidewalks, etc.”

Cedar Sheds Canada’s biggest sellers today are its 8 by 12 shed and 10 by 16 with garage doors, which are made entirely of white cedar, including the runners, joists, wall studs, and siding.

“We average 85-90 sheds per year,” shares Meilleur. “And we build 3-5 high-end shelters per year.”

While he handles sales and deliveries, seven employees handle the production side of the business.

“Pierre and Jérôme, who have 40 years of experience, are in charge of cedar production with Alex,” says Meilleur. “Yvon and Yolan are in charge of building the sheds, and Sam is in charge of the roofing.”

The company builds about two to three sheds per four-day work week, depending on the size of the structure.

“We began construction in a small 20 by 30 part of the molding factory,” Meilleur says. “Then in 2019, we built a 40 by 60 workshop, divided into two sections. There are always two to three sheds under construction.

“Everything is built here. No panel sheds are made.”

Cedar Sheds Canada has consistently upgraded its operation over the years.

“Following my first visit to a shed show, I started purchasing equipment, such as my first Mule 4 in 2017, my Pine Hill trailer in 2019, a Mule 624 in 2021, a bird notcher in 2022, a Joey Lift in 2023, not to mention our door and window suppliers, as well as our 3D builder,” says Meilleur.

“We try to stay as close as possible to the standard that our 3D configurator can produce. But in downtimes, we are more open to trying to find the ‘wow’ effect. During the winter season, I always try to build a shed either with new colors or new options.”

Cedar Sheds Canada’s peak seasons are spring and fall. During the peak season, it takes Meilleur and his team five weeks from sale of a shed to its delivery. During the off-season, the timeframe is cut down to two weeks.

“An 8 by 12 shed takes about 1.5 days to build, and most deliveries are within a 75-100 km radius,” he says. “I do them in the evening after dinner. Customers love it, since they don’t have to take time off from work.

“My deliveries that are more than 100 km away, I do them on Fridays, since the employees are not working.”

About 70 percent of Cedar Sheds Canada’s structures are sold through its website and the 3D configurator. The remaining 30 percent are sold in hardware stores, which handle sales and installation.

“When I started out, I had a lot of ambition,” shares Meilleur. “I wanted to make 150-200 sheds a year and have four or five construction bays. I brought in a business optimization specialist to develop our line and calculate the time losses. However, since our sheds are mostly unique, it is difficult to do assembly-line work.

“We tried dealers, but we didn’t get the desired results. We are the best sellers for our own sheds.”

Like many shed builders, Cedar Sheds Canada has faced increased competition following the COVID pandemic.

“Many people have started building and/or reselling sheds,” says Meilleur. “We stand out for our style and the type of materials we choose.”

But probably his biggest challenge involved shifting the business from milling to building.

“It was about getting my parents, who were still very involved in the business, to accept the direction it was going to take—heading into the unknown, moving from wood processing to construction,” Meilleur points out. “But there’s a saying: an entrepreneur is someone who jumps out of a plane and builds their own parachute during the descent.

“I was trying to get my parents to understand the usefulness of a Mule and trailer to save time, and we all know that time is money. Thanks to the sale of sheds versus just the sale of wood, we have doubled our turnover.”

While Meilleur is proud of what the business has accomplished, he shares that his greatest pride is every time he goes to the Shed Builder Expo and several manufacturers recognize him with his Cedar Sheds Canada shirt.

“They come to see me to tell me how beautiful our sheds are,” he says. “For my team and me, it is very flattering since I consider ourselves a small manufacturer from Quebec, Canada.”

Meilleur appreciates the mutual support and friendship between manufacturers and haulers in the industry.

“Before the last Shed Builder Expo (Knoxville 2025), I went to visit Beachy Barn in Ohio,” he says. “They opened their doors to me without even knowing each other. It creates a beautiful friendship.

“When you ask a question on the Facebook groups for sheds, someone is always ready to give excellent advice. This does not happen in the world of sawmills.”

The future of Cedar Sheds Canada will involve technological upgrades and growth—while allowing Meilleur to devote more time to his family.

“We’re turning to new technologies like artificial intelligence,” he says. “For ordering, our future configurator will be MyShed, with its tracking, inventory, etc.

“It’s all about making things easier for me and allowing me to enjoy life more with my wife and three children. During our busy season, I have to leave the house at 6 a.m. and get back around 9:30 p.m.”

That doesn’t mean Meilleur is slowing down when it comes to growing the business.

On the product side, the company is working with a municipality to develop tiny houses to help young families become first-time homeowners.

And Cedar Sheds Canada is working to expand its territory, trying to make inroads into the northeastern states of the U.S. “I really hope these projects work,” he says.