If you have followed my previous articles on shop automation you might be thinking, “Here he goes again with some out-of-reach, expensive equipment for shed building.”

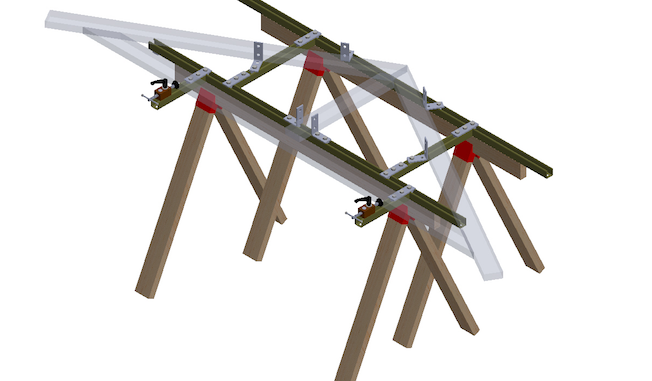

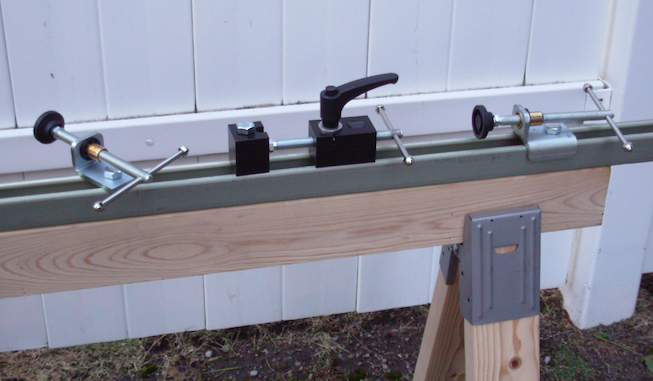

Well, that’s not the case with what I’m about to describe. What if you could build a jig for framing a wall panel out of readily available strut channel, mount it to virtually any bench or base, even saw horses, for less than $1,000? Do I have your attention now?

What is it? A strut channel, which is also called a slotted channel, is found in most every industrial complex. It is commonly used as structural support for pipe and conduit running overhead, hanging HVAC units and ductwork from the ceiling, and for constructing storage racks. However, it has a multitude of other uses and practical applications in any shop environment that requires light structural support.

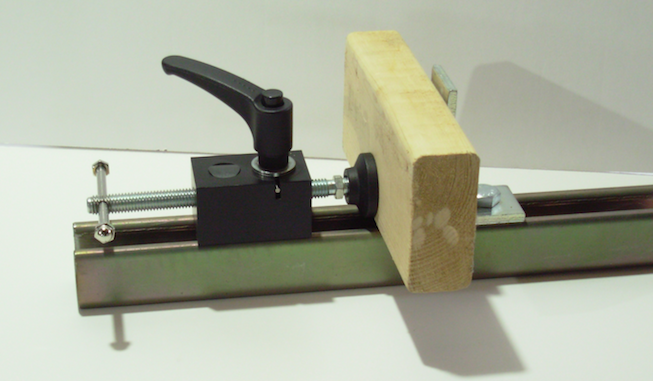

Made by forming sheet steel into a channel, which gives it rigidity and strength, a strut channel’s main attribute is that it is a structurally sound material that requires no welding to fabricate into something purposeful. This makes it an ideal option for constructing a wall framing jig or, for that matter, any other jig needed to repetitively build shed component parts like door and window bucks or roof trusses.

How is it used? Interconnecting pieces of strut channel is accomplished with what seems like an infinite number of fittings, connectors, channel clamps, nuts, and bolts to create virtually anything where structural integrity is required that would typically involve welding pieces of metal together. There is a lot of engineering behind such a basic steel product and simple hardware. The versatility and ease of use makes a strut channel a perfect option for a shed builder looking to increase productivity without a large capital investment.

Where to find it. Many industrial supply companies and hardware stores offer strut channels in cut lengths. Check a local steel distributor for more variety and the best pricing.

Application for shed builders—think outside the box. With a little ingenuity, you can construct a wall framing jig that will allow walls to be framed to exact specifications repeatedly with a less skilled laborer. With little to no measuring, lay the studs in the jig, clamp down, and then nail together. Set up a separate jig to build door and window bucks for each size you offer with a shed. Build these components at a separate work station and then transport them to the wall framing jig for nailing with the rest of the wall frame.

There are no limits to what you might build with a strut channel to make your shop more organized, more efficient and of course a safer work environment.

If you construct a jig that isn’t quite what you want, simply unbolt it and make the necessary adjustment and changes. Extend the length of the jig for different wall heights and lengths. Incorporate window and door openings in the layout of the jig. Since there are no welded pieces, you will have complete control and flexibility to make changes when needed.

But let’s face the fact that shed building is mostly a manual process at many shed shops. Wall studs are laid out on the floor, nailed together, and then stood upright. This is usually done next to a prebuilt shed floor so that the framed walls can be easily lifted onto the shed floor and then nailed down. There are production limits with the typical stick framing process of building sheds. Incorporating a wall framing jig into your shop really involves a change in methodology. If increasing productivity and efficiency are important then a wall framing jig is justified.

Does your shop build sheds as one-offs? One shed built by one builder in a single station? Or maybe your shop has departmentalized tasks based on the skill set of certain builders. One builder may be an excellent roofer while another builder is a better finish and trim guy. So, the worker moves from shed to shed to perform his specialty. Could a framing table enable your shop to produce one or two more sheds per day without adding builders?

However your shop might be laid out, a wall framing jig would be beneficial only if you embrace an assembly methodology for building sheds. In other words, a wall framing jig is one part of a systems approach to shed assembly. You will need the floor space to have multiple sheds in production and room to navigate around each shed, a dedicated measuring and cutting department to supply precisely cut wood, the ability to move materials and components quickly and efficiently from one department to another, and the personnel to dedicate to each department. Like pieces of a puzzle the departments make up the whole production effort. Each department is reliant upon the others.

Shop automation is a different approach to building sheds. Whether you can justify expensive computer operated equipment, or just want to start small with a bolt together wall framing jig, it might be time for your shop to give automation a try.

Mike Kelly from Voytas, Inc. in Syracuse, New York contributed to this article. For more information on Con-Strut-It Strut Channel Clamps email: info@voytasinc.com or visit www.construtit.com.