One of the most important tools for painting sheds is your spray equipment. Without it, the paint process comes to a halt.

Of course, you can always paint your sheds with a brush and roller, but if you’re looking to be efficient and keep up with production, a sprayer is the way to go.

Just like with other pieces of equipment, sprayers can eventually stop working or have issues that you will need to address. Your ability to troubleshoot and possibly fix issues quickly will be important to maintaining an efficient paint operation.

In this article, we’re going to look at the top three most common problems that can compromise spray equipment, along with the best way to troubleshoot them.

The most common type of spray equipment used by shed builders today is an airless sprayer. “Airless” means the equipment is not using air to break up or atomize the paint. The paint is atomized when it’s pushed through a small orifice at high pressure. This is like putting your finger over the end of a water hose.

There are several types of airless sprayers that shed builders use today. They each have their advantages and disadvantages, but their general purpose of atomizing paint without air and allowing you to spray large volumes of paint efficiently is the same.

The most common is an electric motor-driven pump on wheels. Wall-mounted pumps are also common, some of which are air-driven motors rather than electric.

Now, let’s take a look at the top three problems/solution scenarios that impact sprayers. While some of the issues may apply to all types of airless sprayers, all of the issues apply to the common electric airless.

Expertise for this article was provided by John Cutlip, store manager of PPG Paints in Wooster, Ohio. John is a certified Graco and Titan Spray Equipment Technician and has over 28 years of experience working on spray equipment.

(Caution: never attempt to perform any maintenance on a pump until all pressure in the system is relieved.)

ISSUE 1: PUMP IS NOT PRIMING OR PICKING UP

With an airless pump, you need to “prime” the pump before you start spraying. This will remove whatever coating/cleaner that may have been left in the pump and will load the paint you are about to use. Prime the pump first, and then prime the hose/gun.

If you hear the pump running but nothing is coming out of the prime hose, or if it’s turned to spray and nothing is coming out of the gun, your pump is not priming or picking up. Start your troubleshooting with these suggestions:

• Check all filters/screens. See if they are clean or if they are clogged. With most pumps, there should be a screen at the bottom of the pickup tube. Also, there may be a manifold filter in the pump and a filter in the gun. If the filters are clean, it could be that either the intake or outlet ball is stuck on the seat.

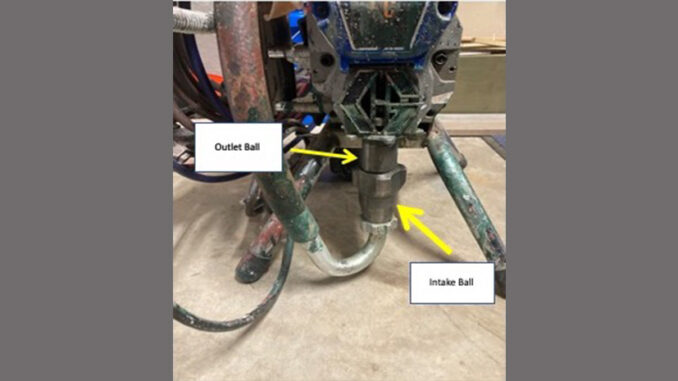

• Make sure the intake ball or outlet ball is not stuck on the seat. The intake ball is a large ball located in the foot valve at the bottom of your cylinder where your siphon tube attaches. The outlet ball is a small ball located inside the piston valve at the end of your piston. Before taking the pump apart to inspect, you can try tapping the area with a rubber mallet or block of wood while the pump is running. This will help knock the ball loose and allow the pump to pick up. Be careful not to tap so hard, as you could damage the foot valve.

• Don’t overheat your packings. Remember, the material is what cools your pump’s packings. If you run your unit too long without picking up material, it is possible to overheat your packings and damage them. Note: if your unit does not pick up or prime within a minute, stop and check the previous troubleshooting ideas.

ISSUE 2: PUMP STOPS RUNNING OR WILL NOT POWER ON

If you’re using an electric-driven airless and it will not turn on or it stops running during use, troubleshoot with these suggestions:

• Ensure that you have enough power supply for the pump. Generally, they need 20 amps and not on a shared circuit.

• If using an extension cord, make sure it is the correct AWG size wire to supply the pump with the proper amps. Rule of thumb is the shorter the extension cord, the better. Longer extension cords should be at least 10 AWG.

• If the pump stopped during use, let it cool down for 15 minutes before restarting. Most pumps have a thermal protection circuit that will kill the motor if it is starved for power. This switch will reset itself once cooled.

ISSUE 3: POOR SPRAY PATTERN

A key piece to an airless sprayer is the spray tip. Available in various sizes, tips are designed to give you an even and consistent pattern and flow of paint.

Here are some common issues experienced with spray tips and possible troubleshoots:

• Reduced flow from the tip.

— Check that your gun filter is clean.

— Check for leaks around the nozzle when the pump is pressurized and the trigger is not pulled.

— Increase the pressure setting on the pump.

• Lines or Fingers in the Spray Pattern.

— Check that the tip is clean. If it is a reverse tip, turn it and spray through it backward to flush out.

— Turn the pressure up on the pump.

— Try a new tip, as the current tip may be worn out. (Normally, you will get 55-65 gallons before your tip starts to lose performance.)

• Heavy lines only on the outside edges of the fan pattern.

— Turn the pressure up on the pump.

— Paint may be too thick for this tip size to atomize.

— Consider a tip with a larger orifice.

AVOID PROBLEMS BEFORE THEY HAPPEN

Remember, one of the best ways to reduce issues with your sprayer is preventive maintenance. Flush it out with water or cleaner after use and keep your tips and guns clean. Also, periodically clean your filters and screens.

If the troubleshoots outlined in this article do not fix the issue, consider reaching out to your local spray equipment mechanic or call the spray equipment manufacturer for more assistance.

ALSO SEE:

Maximize Your Paint Process, Nov. 17, 2021

What’s the Key to Ensuring Paint Consistency? Mix, Mix, Mix!, Jan. 19, 2022

Painting in Cold Temperatures, March 30, 2022

How Efficient is Your Paint Process?, May 18, 2022

Best Practices for Touching Up a Shed, July 20, 2022

Best Practices to Avoid Debris in Paint, Sept. 21, 2022

Best Practices for Spraying Waterborne Semi-Transparent Urethane Coatings, Nov. 29, 2022